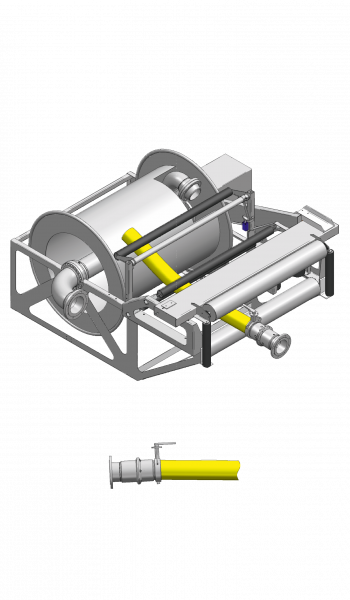

Bij het beladen van schepen kunnen milieubelastende dampen vrij komen die veilig moeten worden afgevoerd. WLT heeft hiervoor een dampretourhaspel ontwikkelt. De aangedreven haspel zorgt voor het gecontroleerd afwikkelen en oprollen van de dampretourslang. De unit wordt geplaatst op de steiger en kan aangesloten worden op de dampretourinstallatie. De voordelen met betrekking tot functionaliteit, milieu, veiligheid en levensduur zijn evident.

Om aan deze bezwaren tegemoet te komen ontwikkelden wij de dampretourhaspel. De aangedreven haspel zorgt voor het gecontroleerd afwikkelen en oprollen van de dampretourslang. De unit wordt geplaatst op de steiger en kan aangesloten worden op de dampretourinstallatie. De voordelen met betrekking tot functionaliteit, milieu, veiligheid en levensduur zijn evident.